Direct

Digital

Manufacturing

Where a technical problem finds a solution.

Tenco DDM supports your project – from idea to serial production.

For over 10 years, customers have been counting on our technical engineering knowledge to help them create, improve or optimise their solutions.

Whether it’s design and engineering, prototyping, production or assembly: our wide knowledge of technical solutions and materials gives us the power to solve complex issues in an innovative way.

Let’s start creating together.

The Part(ner)

you need,

Always!

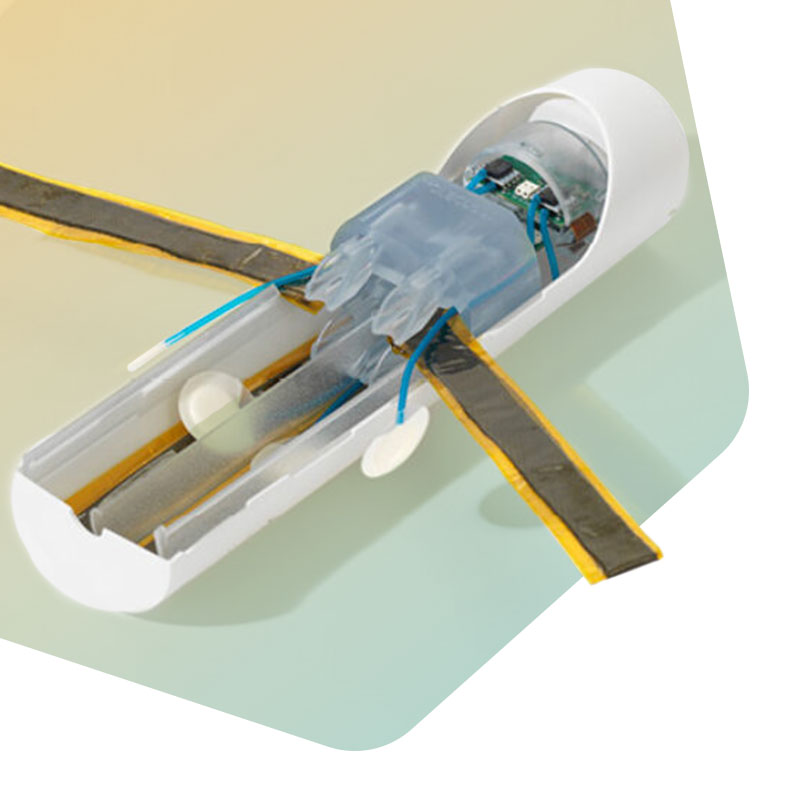

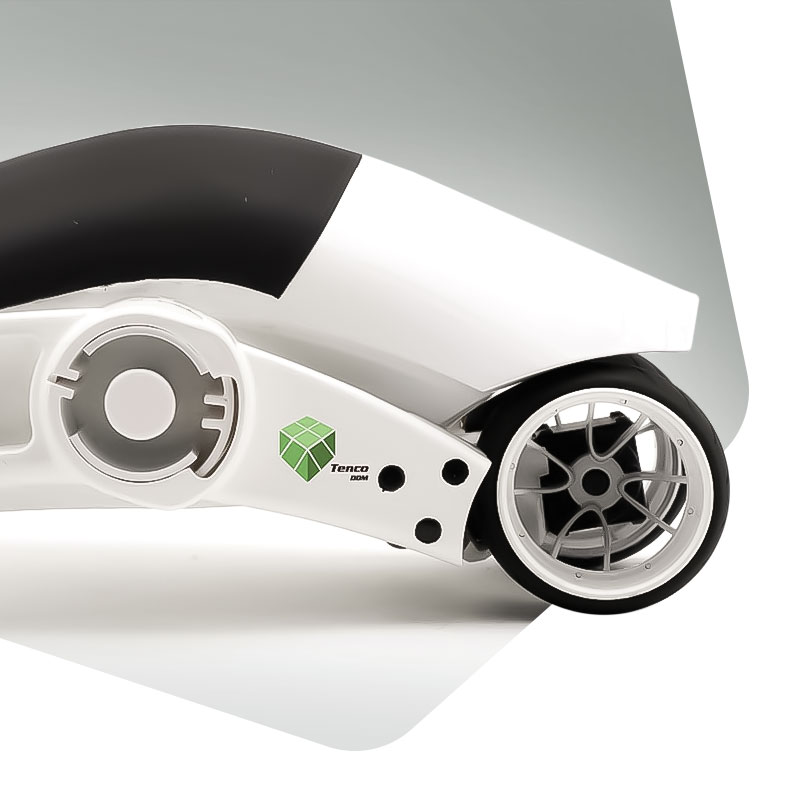

The leading edge

Tenco has been a long-term partner of the Belgian Solar team. Our knowlegde, techniques and technical materials make it possible to produce parts in very low numbers and have the optical properties to meet the very strict requirements for road safety and performance. At the same time, their complex shape gives this team a leading edge to become world champion.

Industries

Machine designers and builders

People designing and building machines have to work on ever tighter budgets. Therefore, innovation is paramount. We combine multiple materials and techniques to optimize the design and thus reduce weight and costs.

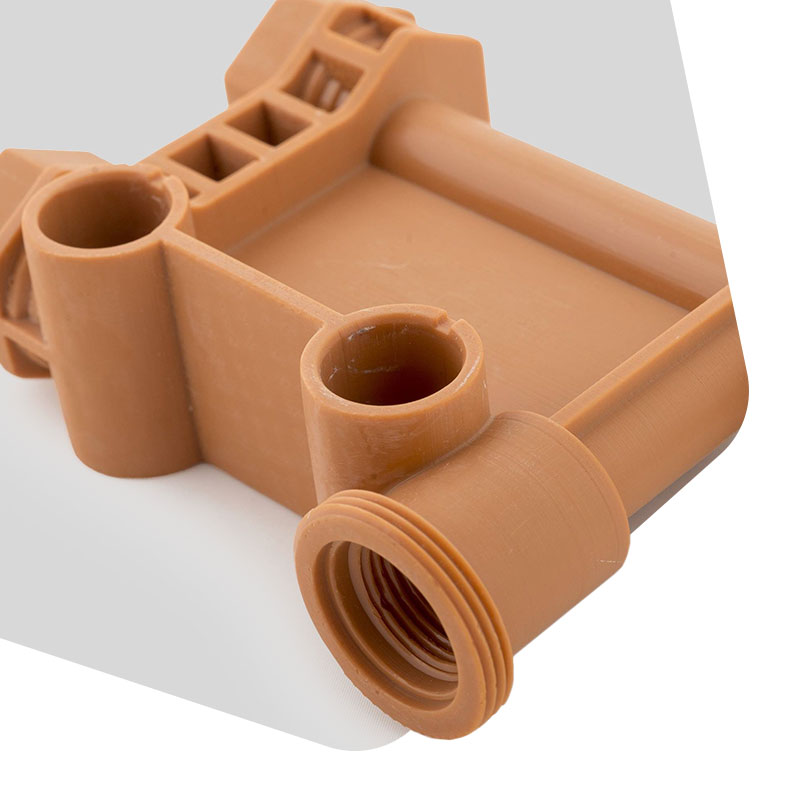

Medical devices

With our low-volume production capabilities, Tenco DDM is the perfect partner for medical device companies. Our solutions include housings and accessories, which we finish with certified coatings to make them suitable for the demanding environments these parts are used in..

Jigs and tools

Manufacturing precision and efficiency are key when you need to increase the quality of your product or produce higher volumes. To ensure stable processes, we design and produce jigs and aids that will help you.

Innovative projects

Proud

to mention

some of

our customers